Making embodied carbon part of the decision-making process in building design

Globally, buildings account for 39% of all carbon emissions. While we have been discussing and tackling operational carbon for some time, we have concentrated much less on the impacts of embodied carbon as it accounts for only about 11% in a building’s life cycle(1).

Embodied carbon is the carbon emitted from the extraction, manufacture, transportation, construction, maintenance, deconstruction and end of life application or disposal of materials.

In our quest to keep global temperatures from rising more than 1.5 degrees Celsius, the coming decade is critical. We need to reduce our emissions and the speed of this reduction matters.

As such, we are rethinking the way we frame the story about embodied carbon to account for what the World Green Building Council has called “upfront emissions”(2). While operational carbon is emitted on a steady basis throughout the building’s service life, 80% of embodied carbon emissions are released between material extraction to construction, or cradle-to-gate, making this early phase of a building’s life cycle extremely carbon intensive.

Understanding and prioritizing our material choices in terms of their embodied carbon impact needs to become an immediate area of focus of building design and construction. This will take concentrated effort and open sharing of knowledge within our AEC ecosystem to accelerate the learning that is required of our industry. I am grateful to organizations such as the Carbon Leadership Forum(3) (CLF) and the London Energy Transformation Initiative(4) (LETI) that have been instrumental in accelerating our journey.

The largest local benchmarking study we have seen came from the students in Kelly Alvarez Doran’s studio called Towards Half at the Daniels Faculty of Architecture, Landscape and Design. We contributed one of our mid-rise projects (DUKE Condos) for the students to perform a cradle-to-gate embodied carbon study. We then participated in a crit panel with nine other architectural firms, all of whom had contributed projects, where students presented their findings back to us in a very digestible way. Seeing one’s work measured against a new metric is humbling and can provide new insight and methods for evaluation.

Inspired by this experience and in alignment with BDP Quadrangle’s Zero-Carbon Roadmap, we took our learnings and conducted our first embodied carbon study. Our goals were:

- to quantify the emissions, identify the largest contributors, and subsequently provide options for quantified reduction, and

- to understand the workflow of a cradle-to-gate life cycle assessment and share the learning process with our client.

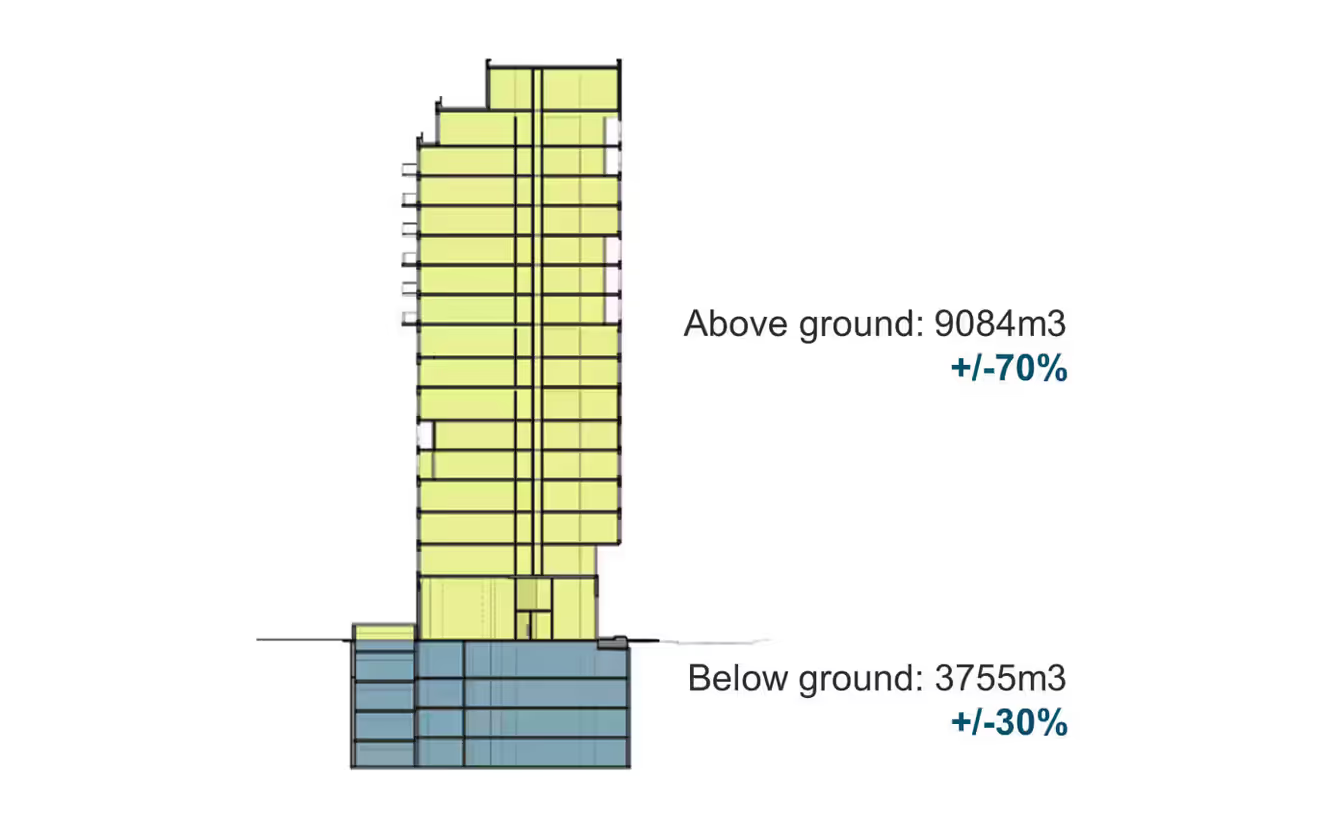

The building is a 16-storey multi-unit residential building with four storeys of underground parking, a cast-in-place concrete structure, a rainscreen cladding and approximately 300 units in early design phase. We used the One-Click LCA software to perform our study. The learning curve was steep at the outset as we came to grasp the tool’s complexity and sourced the Environmental Product Declarations required to verify the emissions of each building component.

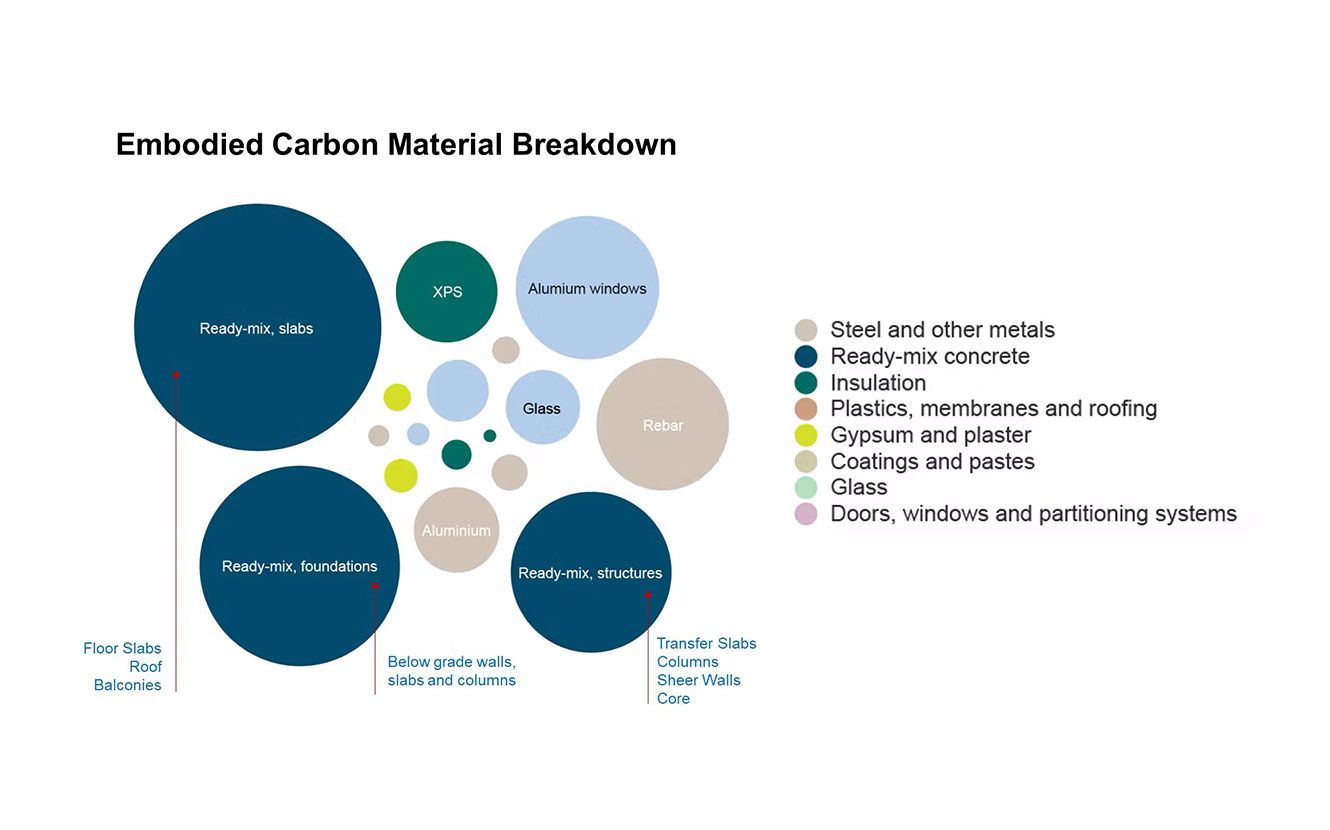

The software generates graphics that clearly communicate material breakdowns allowing us to quickly identify the heaviest emitters and work on providing alternative solutions. From the diagram below, we learned that concrete made up 67% of the carbon emissions. A third of this was below grade.

Following the first principles of reduce, reuse, recycle, we began by questioning the basic assumptions. Could we build less? Could we use materials with a lighter footprint?

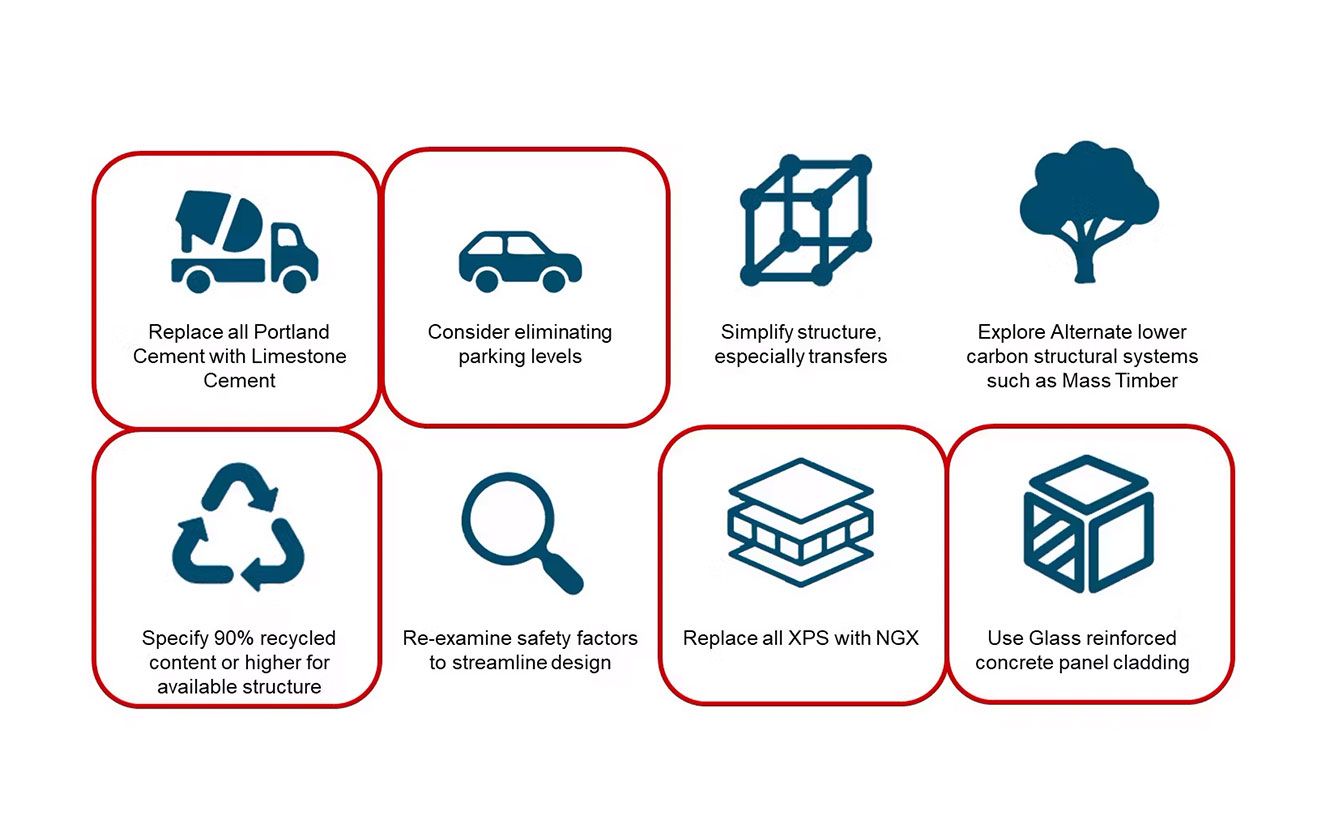

We learned that each level of underground parking was responsible for approximately 40 kilograms of carbon dioxide equivalent per square meter (KgCo2e/m2) or 7% of the building’s total embodied carbon emissions. We also learned that replacing the Portland cement by specifying Portland-Limestone Cement or General Use Limestone (GUL) led to a 17% savings. We systematically evaluated a handful of other scenarios and landed on the following recommendations:

The benchmarks developed by the U of T studio for a similar scale of building ranged from 366 to 615 KgCo2e/m2. Our baseline model of 568 KgCo2e/m2 sat in the top third of this range. Following these recommendations resulted in a 32% decrease or a final value of 383 KgCo2e/m2.

Our key take-aways:

- Simplify structure, especially structural transfer slabs;

- Build up not down;

- Explore alternate structural systems with lower carbon footprints such as:

- mass timber;

- hollow core slabs, bubble deck, waffle slabs;

- Specify 90% recycled content or higher for available structural steel shapes;

- Re-examine structural safety factors to streamline design.

Most importantly, you can’t manage what you don’t measure. Many of these strategies cost less rather than more. If you are interested in understanding the impacts of your material choices and options for improvement, please speak to us.

Special thanks to Sarah Hassan and Jason Freedman for their hard work on this evaluation.

Source references:

1. World Green Building Council https://www.worldgbc.org/news-media/WorldGBC-embodied-carbon-report-published

2. World Green Building Council https://www.worldgbc.org/news-media/WorldGBC-embodied-carbon-report-published

3. Carbon Leadership Forum, https://carbonleadershipforum.org

4. London Energy Transformation Initiative, https://www.leti.london/

5. City of Toronto Review of Parking Requirements for New Development – City of Toronto